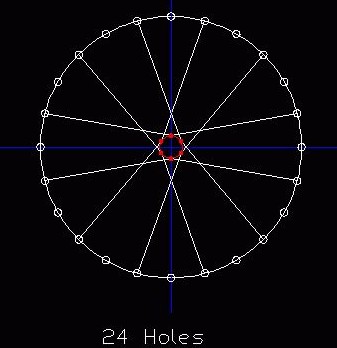

4) Lacing pattern

Lacing: correct lacing patterns with straight-pull spokes must be as shown below.

Maximum spoke tension:

Refer to manuals

CyberFront SPD3+ CyberRear

SPD3+

CyberFront SPC3+ CyberRear

SPC3+

Warning:

spoke lacing and tensioning require skills and experience, refer to an expert

professional wheel builder for these operations.

5) Spoke Materials

Steel

Spokes: Hub

f langes accept standard spoke heads however

we recommend to use only high quality "butted" steel spokes.

Butted spokes are lighter and allow a better spoke

aligningment that translates in a reduced stress of

the parts and an overall stiffer lacing.

Berd

spokes:

Flanges

are designed to fit Berd spokes too.

All edges are well rounded thereafter "Tangential

Straightpull Inserts" are not necessary.

Consequently adjust Table A lenghts as follows:

-

subtract 2mm from Table values

if "Without

Tangential Straightpull Inserts"

- keep

same values on Table

if "With

Tangential Straightpull Inserts"

Berd Tangential Straightpull Insert

Carbon-Titanium

Spokes: Hub

flanges accept composite spoke that feature

standard thin metal ends (Titanium

or Steel) since

the short metal head should be well bendable in order to get the spoke correctly

aligned with the rim.

When lacing Carbon Titanium spokes make sure to add this important step to

the lacing process:

- As spokes are fully tensioned settle

spoke heads (before

final truing).

- To settle

spoke heads

push the metal area of the spoke immediately after the hub flange with

a small wood/plastic rod in order to settle them permanently to the exact

direction.

- Then execute the final truing.

NOTE:

SPD3+

and SPC hubs feature 3D angled spoke flanges thereafter the above process

should be done only for checking and eventual minimal corrections.

Anyhow

always remind that cabon-metal spokes are extremely

sensitive to the following:

- Twist: thread-to-head section should never get twisted not even during lacing.

- Spoke to nipple-alignment: each nipple should get perfectly aligned with

its spoke.

-

Avoid exposure to hi-temperatures

as behind car windows under hot sun, transport, storage etc.

-

Avoid hits with any hard object

during

riding, transport,

storage etc.

Fully

respect these basic info before and after installation.