SCR - 058c 580g. (M size)

A performance sculpture that's lighter than anything else!

Fork:

290g

Frame:

580g (M size)

Fittings:

3D cnc AL 7075

T6

Dropouts:

3D cnc AL 7075

TX

Structure:

MIF

carbon

technology

Finshing:

natural matt 3K carbon

Graphics:

see-thru

gloss

Sizes:

S-M-ML-L

Fully

hand-made here in north Italy by passionate techincians and engineers.

Reaches

an astonishing performance-to-weight ratio thanks to the proprietary MIF carbon

technology and our time consuming wrapping technique.

No

shortcuts!

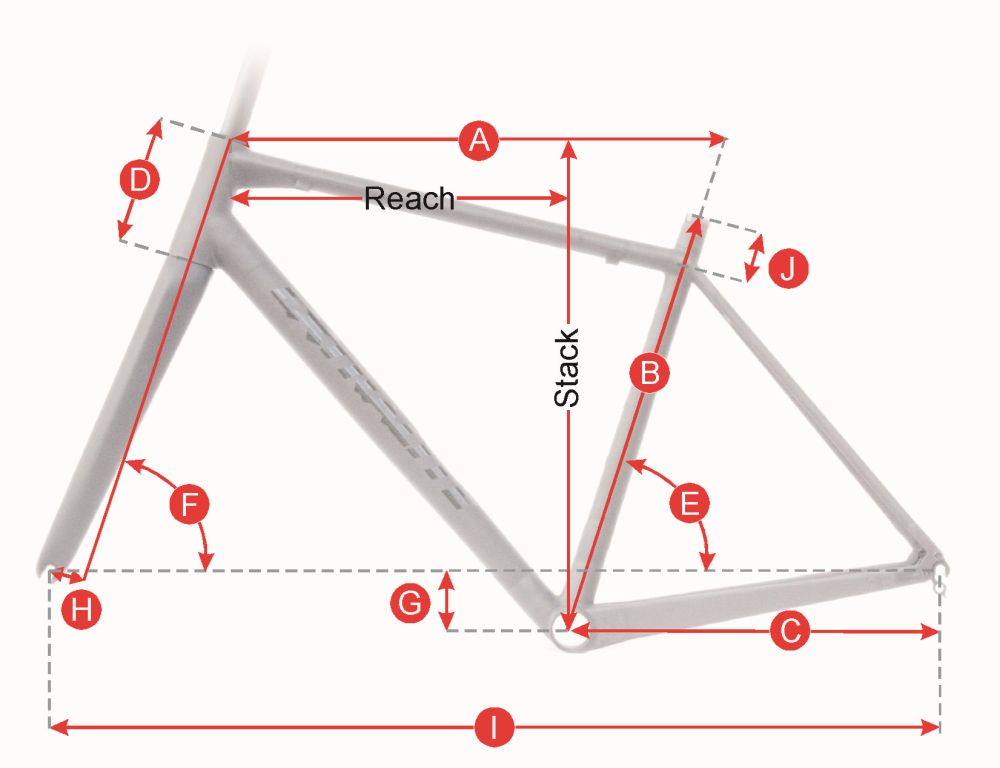

Geometry

|

Measures

in mm

|

S

|

M

|

M-L

|

L

|

Custom

|

| Reach |

385

|

390

|

399

|

403

|

-

|

| Stack |

522

|

541

|

560

|

579

|

-

|

| A |

530

|

550

|

565

|

580

|

-

|

| B |

450

|

480

|

500

|

520

|

-

|

| C |

402

|

404

|

404

|

406

|

-

|

| D |

X120

|

140X

|

160

|

180

|

-

|

| E |

74.5

|

73.5

|

73.5

|

73

|

-

|

| F |

72.5

|

73

|

73

|

73.5

|

-

|

| G |

72

|

70

|

70

|

68

|

-

|

| H |

43

|

43

|

43

|

43

|

-

|

| I |

974

|

983

|

998

|

1005

|

-

|

| J |

-

|

-

|

-

|

-

|

-

|

| Weight (+/- 5g) |

570

|

580

|

595

|

610

|

-

|

Framesets come equipped with fork, headset & clamps

Assembling

components standards:

Seat

tube: Ø27.2mm

Seat

tube clamp::

Ø30.0mm

BB

shell:

BB91-42

- Ø42x86.5mm

Steerer

tube: 1 1/8 top - 1 1/2 bottom

Rear

dropouts: QR - 10x130mm

Front

dropouts: QR - 9x100mm

Rims:

700C

rim-brake only

Max

tyre width: 28mm

Configure

your shifter type (BT, Di2 or mechanical) on the SCR-058 ordering page of

our web-shop

Top tube flat-oval section blends into steer tube with a nice fin that sensibly helps to point the apex of hi-speed turns with laser precision.

Generously dimensioned downtube ensures torsional rigidity by the log of its wide round section

Beefy tapered chainstays feature progressively increasing lamination layers, this translates into livelier reactions under acceleration

Crank and fork bearings contact the frame through precisely cnc'ed AL7075T6 fittings that fully void looseness or squeaks

Seat-tube enlarges its section while descending, then widens up at the BB area, all laminated with tricky twice progressive layering

Downtube flattens at bottle cage fittings and widens up to oval at the BB shell to keep crank loads under good control

Top tube and seatstay merge just right where FEM analysis suggests they should in order to manage well the sprinting stresses

The

extreme reduction of stress riser areas is from the beginning the base of

Extralite's engineering philosophy

3D

dropouts: these tiny cnc sculptures can withstand to countless QR opening

& closings, that unlike the commonly used carbon dropouts

Additionally the SCR dropouts offer a truly solid fitting of the rear hub-axle and wheel plus the rear derailleur bolts on very safely too

More details are coming by 2024 spring..

Stay tuned!

![]()

100% made in Italy